Seal Healing Honeycomb Material

Self-Healing Hull Specification

Overview:

- Purpose: To create a ship hull capable of autonomously repairing minor to moderate damage, enhancing durability, and reducing maintenance costs.

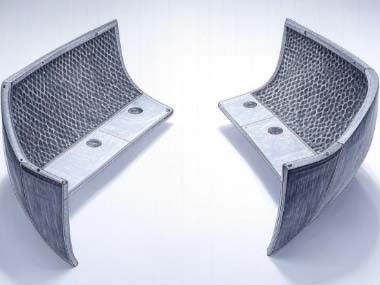

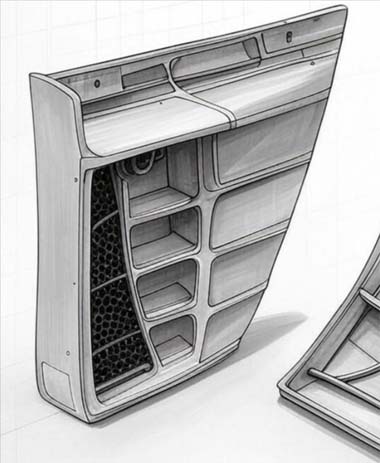

- Design Concept: A composite structure where a honeycomb core is sandwiched between two layers of protective skins, with the core filled with a self-healing gel.

Structural Components:

-

Outer Skin:

- Material: High-strength, which provides resistance to impacts, corrosion, and UV radiation.

- Thickness: variable.

- Features:

- UV protection coating.

- Anti-fouling treatment to prevent marine growth.

-

Inner Skin:

- Material: A lighter, less rigid composite, such as carbon fibre reinforced polymer, to maintain structural integrity while allowing flexibility for the self-healing mechanism.

- Thickness: variable.

- Features:

- Sound and thermal insulation properties.

-

Honeycomb Core:

- Material: lightweight strength and rigidity.

- Cell Size: 6-10 mm per cell to balance weight with strength.

- Height: 20-30 mm.

- Purpose: Provides structural support while housing the self-healing gel.

-

Self-Healing Gel:

- Composition: A polymer-based gel with microcapsules containing healing agents (like dicyclopentadiene) and catalysts (like Grubbs' catalyst). When damage occurs, the capsules break, releasing the chemicals to polymerize and heal the breach.

- Properties:

- Non-toxic, marine-safe.

- Temperature and pressure resistant.

- Gel should be viscous enough to stay in place but not so much that it clogs or leaks from minor punctures.

Self-Healing Mechanism:

- Trigger: Mechanical damage or pressure change causing microcapsules to rupture.

- Process: Upon breach, healing agents mix and polymerize, filling and sealing the damage. This process can be accelerated with slight heating or pressure change.

- Efficiency: Expected repair for minor to moderate damage (up to 15 mm diameter holes) within 24 hours under optimal conditions.

Installation and Maintenance:

- Installation:

- Layering process in a controlled environment, ensuring no air or moisture is trapped between layers.

- Gel infusion must be precise to avoid over or under-filling cells.

- Maintenance:

- Regular checks for the integrity of both skins and the functionality of the gel using non-invasive diagnostic tools like ultrasound or infrared imaging.

- Potential replacement or re-infusion of gel if significant degradation or depletion occurs.

Testing and Validation:

- Lab Tests: Impact resistance, puncture tests, cyclic fatigue, environmental exposure.

- Field Tests:

- Real-world application on small vessels before full-scale implementation on larger ships.

- Monitoring with sensors embedded in the structure for real-time performance data.

Environmental Considerations:

- End-of-life: Considerations for recycling or disposal of the materials, focusing on the environmentally friendly decomposition of the gel and composites.

Patent and Intellectual Property:

- Research and Development: Ensure all materials and processes are either patented or the use is licensed appropriately to avoid infringement.