Hydrogen Fuel Cells

Hydrogen Powered Fuel Cell Specification

1. General Description

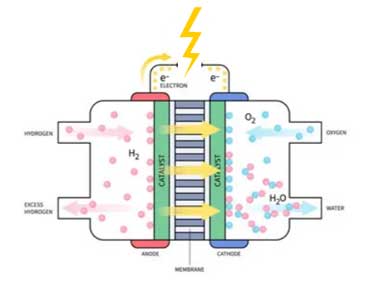

- Type: Proton Exchange Membrane (PEM) Fuel Cell

- Application: Suitable for vehicles, stationary power generation, and portable devices.

- Advantages:

- High power density

- Quick start-up

- Low operating temperature

2. Performance Specifications

- Power Output:

- Nominal Power: 5 kW - 100 kW (scalable based on stack size)

- Peak Power: Up to 120% of nominal for short durations

- Efficiency:

- System Efficiency: Approximately 50-60% (LHV - Lower Heating Value)

- Peak Efficiency: Up to 65% under optimal conditions like full load and ideal temperature

- Voltage:

- Nominal Voltage: Variable, typically around 40-60 V per cell stack

- Operating Voltage: 0.6-0.8 V per cell, depending on load and hydrogen quality

- Current Density:

- Max Current Density: 1.5 A/cm², can vary with membrane and catalyst efficiency

- Response Time:

- Startup Time: Cold start less than 30 seconds (from -20°C to operational with pre-heating)

- Load Response: Immediate response to load changes due to quick proton exchange

3. Fuel Specifications

- Hydrogen Quality:

- Purity: ≥99.97% to prevent catalyst poisoning

- Maximum Impurities:

- Water: <5 ppm

- CO: <1 ppm, as it can poison the platinum catalyst

- O₂: <2 ppm

- Other hydrocarbons: <2 ppm

- Fuel Pressure:

- Operational Pressure: 1-5 bar (variable by system design for optimal diffusion)

- Fuel Storage:

- Type IV composite hydrogen cylinders for high-pressure storage

- Liquid hydrogen tanks for larger systems or long-duration storage

4. Environmental & Operating Conditions

- Operating Temperature:

- Cell: 60°C to 80°C for efficient proton exchange

- System: -20°C to 50°C (ambient) with appropriate cooling and heating mechanisms

- Humidity:

- Operating Humidity: 20% to 95% RH, membranes require hydration for conductivity

- Altitude:

- Operational: Up to 2,000 meters without derating, higher altitudes may require pressure adjustments

5. Durability & Lifetime

- Lifetime:

- Expected: >5,000 hours for automotive; up to 40,000 hours for stationary applications

- Degradation Rate: <10 µV/h under normal operation

- Cycling:

- Start/Stop Cycles: >10,000 for automotive applications due to frequent use

6. Physical Specifications

- Dimensions:

- Varies by application; for a 100 kW system, approximately 1 m³ including auxiliaries

- Weight:

- Approximately 50-100 kg per 50 kW (excluding hydrogen storage, varies with materials used)

7. Safety Features

- Hydrogen Leak Detection: Integrated sensors for immediate action

- Thermal Management: Cooling systems to maintain optimal temperature and prevent overheating

- Overpressure Protection: Pressure relief valves and system shutdown capabilities

- Electrical Safety: Compliance with IEC 62282-3-100 for fuel cell systems to ensure no electrical hazards

8. Standards Compliance

- ISO 22734: Hydrogen generators using fuel processing technologies

- ISO 14687: Quality of hydrogen for PEM fuel cells

- IEC 62282: Fuel cell technologies

9. Maintenance

- Service Intervals: Annual inspection recommended; component-specific maintenance as per manufacturer's guidelines

- Maintenance Tasks:

- Replacement of air filters

- Cleaning or replacement of humidifiers

- Inspection of electrical connections

10. Environmental Impact

- Emissions: Water vapor as primary byproduct; zero CO2 emissions during operation, contributing to reduced greenhouse gas emissions

Keywords

hydrogen fuel cells pem fuel cell proton exchange membrane energy efficiency power density hydrogen quality hydrogen purity fuel cell efficiency voltage output current density response time startup time load response hydrogen pressure fuel storage liquid hydrogen composite cylinders operating temperature humidity altitude durability lifetime degradation rate cycling physical dimensions weight safety features leak detection thermal management overpressure protection electrical safety standards compliance iso 22734 iso 14687 iec 62282 maintenance service intervals environmental impact zero emissions water vapor green energy sustainable energy