Hydrogen Fuel Cells

Hydrogen Powered Fuel Cell Specification

1. General Description

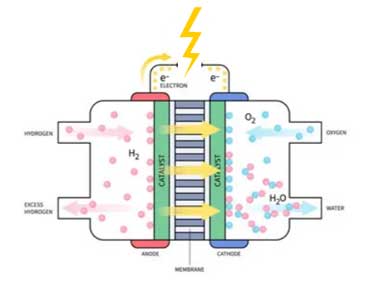

- Type: Proton Exchange Membrane (PEM) Fuel Cell

- Application: Suitable for vehicles, stationary power generation, and portable devices.

- Advantages:

- High power density

- Quick start-up

- Low operating temperature

2. Performance Specifications

- Power Output:

- Nominal Power: 5 kW - 100 kW (scalable based on stack size)

- Peak Power: Up to 120% of nominal for short durations

- Efficiency:

- System Efficiency: Approximately 50-60% (LHV - Lower Heating Value)

- Peak Efficiency: Up to 65% under optimal conditions like full load and ideal temperature

- Voltage:

- Nominal Voltage: Variable, typically around 40-60 V per cell stack

- Operating Voltage: 0.6-0.8 V per cell, depending on load and hydrogen quality

- Current Density:

- Max Current Density: 1.5 A/cm², can vary with membrane and catalyst efficiency

- Response Time:

- Startup Time: Cold start less than 30 seconds (from -20°C to operational with pre-heating)

- Load Response: Immediate response to load changes due to quick proton exchange

3. Fuel Specifications

- Hydrogen Quality:

- Purity: ≥99.97% to prevent catalyst poisoning

- Maximum Impurities:

- Water: <5 ppm

- CO: <1 ppm, as it can poison the platinum catalyst

- O₂: <2 ppm

- Other hydrocarbons: <2 ppm

- Fuel Pressure:

- Operational Pressure: 1-5 bar (variable by system design for optimal diffusion)

- Fuel Storage:

- Type IV composite hydrogen cylinders for high-pressure storage

- Liquid hydrogen tanks for larger systems or long-duration storage

4. Environmental & Operating Conditions

- Operating Temperature:

- Cell: 60°C to 80°C for efficient proton exchange

- System: -20°C to 50°C (ambient) with appropriate cooling and heating mechanisms

- Humidity:

- Operating Humidity: 20% to 95% RH, membranes require hydration for conductivity

- Altitude:

- Operational: Up to 2,000 meters without derating, higher altitudes may require pressure adjustments

5. Durability & Lifetime

- Lifetime:

- Expected: >5,000 hours for automotive; up to 40,000 hours for stationary applications

- Degradation Rate: <10 µV/h under normal operation

- Cycling:

- Start/Stop Cycles: >10,000 for automotive applications due to frequent use

6. Physical Specifications

- Dimensions:

- Varies by application; for a 100 kW system, approximately 1 m³ including auxiliaries

- Weight:

- Approximately 50-100 kg per 50 kW (excluding hydrogen storage, varies with materials used)

7. Safety Features

- Hydrogen Leak Detection: Integrated sensors for immediate action

- Thermal Management: Cooling systems to maintain optimal temperature and prevent overheating

- Overpressure Protection: Pressure relief valves and system shutdown capabilities

- Electrical Safety: Compliance with IEC 62282-3-100 for fuel cell systems to ensure no electrical hazards

8. Standards Compliance

- ISO 22734: Hydrogen generators using fuel processing technologies

- ISO 14687: Quality of hydrogen for PEM fuel cells

- IEC 62282: Fuel cell technologies

9. Maintenance

- Service Intervals: Annual inspection recommended; component-specific maintenance as per manufacturer's guidelines

- Maintenance Tasks:

- Replacement of air filters

- Cleaning or replacement of humidifiers

- Inspection of electrical connections

10. Environmental Impact

- Emissions: Water vapor as primary byproduct; zero CO2 emissions during operation, contributing to reduced greenhouse gas emissions